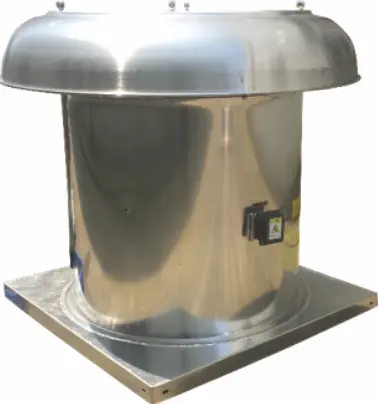

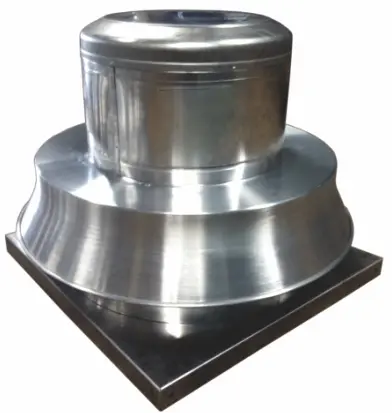

Roof Fan

Aluminum alloy roof fan is specially designed to give service in applications of industry, agriculture and large-space use in civilian. Our products are formed by high-tech molds, made by spinning equipment, and undergo strict quality control testing to ensure product trouble-free starting.

- There are 300-1000 eight device numbers of the impeller diameter of RCR aluminum alloy roof fan.

- The serial wind amount is 400-48500m3/h.Static pressure is 25-1100Pa.

PRODUCT aDVANTAGES

- RCR aluminum alloy roof fan is driven by associated mode. The engine is outside the airlow, isolated from the emited flow. It is more suitable to remove the polluted aas with smoke dust, oil stain and warm humid.

- This product is certified by National Fire Control Test Center. It can continuously work more than 30 minutes in 280C. It meets the demand of fire control for fans.

- RCR aluminum aloy roof fan can be made into aeneral tvpe, explosion proof tye and emitted smoke for fire control type, depending on different use environment and transport media.

- Accord with fluid mechanics hyperbolic linear rawalpindi, overall time nozzle shape impeller diversion mouth, strengthen diversion effect, avoids gas turbulent. Impeller diversion mouth and fully fit, effective control of air distribution and reduce noise; A flow pattern design cowl cylindrical, avoid air turbulence, effective appear right-angle turns to reduce noise.

- The impeler of RCR aluminum alloy roof fan is aluminum alloy, backward centrifugal inclined wheel, bear non-overloaded feature; Its balance level is ISO G2.5. It makes the airflow structure smooth and operates steady.

- Using high-speed rotating impeler in dorsal form negative pressure, active spare motor chamber hot air; The cold air add drive cavity, forced cooling drive system; Prolong the motor, the service life of the bearings.

- Drive cavity non-machined covers adopt stainless steel clasp fixed, unarmed can open, daily maintenance convenient and fast; All maintenance replacement in roofing movements, significantly reducing maintenance workload finish.