Jet Fan

The company has designed and developed ADF series jet fans in combination with the years of tunnel ventilation experience and fan development strength. According to the different air intake forms, it can be divided into ADF-K unidirectional jet fan and ADF-T bidirectional jet fan. ADF-K jet fan, generally used for one-way ventilation. When the fan reverses in special conditions, it can provide 50%-80% forward thrust. ADF-T jet fan can be used for two-way ventilation, which is convenient for users to control the direction of airflow. The thrust force of the fan is basically equal when the fan is forward and backward. ADF series jet fans have 12 kinds from No.4 to No.16, non-standard can be provided per your order.

Jet Fan

The jet fan is a sort of axial fan mainly used in a longitudinal ventilation system for road, railway, metro and underground railway tunnel.

In operation, part of the airflow passing through the tunnel will be sucked in the jet and jetted out at high speed by means of fan impeller. As the jet from the fan diffuses, it transfers energy to the tunnel airflow and creates an increase in static pressure which causes air to flow ahead. When the airflow velocity slows down to a certain value, the next jet fan unit along the tunnel will work. In this way, the purpose of drawing in fresh air at one end of the tunnel and expelling stale air at the other is realized.

product Advantages

- With a wide range of performance, up to 2100 Newtons of thrust for one type of fan, the user has a wider choice.

- The advanced aerodynamic design of the fan results in high efficiency, high thrust and low noise.

- The blades and hubs are made of aluminum alloy die-casting, which have been inspected by metallographic analysis and X-ray flaw detection, and have sufficient strength.

- Precisely balanced impeller makes the fan run balanced and meets the requirement of high speed operation.

- Equipped with special motor, it can operate reliably for a long time under the environment of -25℃~50℃. The life of the motor bearings can reach more than 20,000 hours according to C50 standard; that is, the average life is 100,000 hours according to ISO281 standard. The motor junction box is placed outside the fan casing, which is convenient for users’ wiring.

- Fan impeller design has taken into account the coefficient of thermal expansion and strength requirements at high temperatures, the special motor can ensure reliable operation for more than one hour at a temperature of 250 ℃ environment. (Note: the fan should be overhauled or replaced after high temperature operation by fire).

- Reliable, lightweight and reasonable structure, easy to dismantle and install, convenient for users to maintain.

Structural Features

- Flow collector

A streamlined flow collector improves flowing field, enabling a higher efficient fan an decreasing fan sound level. - Silencer

The fan section is equipped with inlet and outlet mufflers at both ends. The muffler is a two-layer cylinder structure, with galvanized perforated plate inner cylinder covered with high-efficiency sound-absorbing materials, and the outer cylinder is made of high-quality galvanized steel, and the parts are connected by stainless steel rivets and screws, which avoids the damage of the galvanized layer caused by burning welding. The structure of the muffler is light and beautiful. - Fairings

The streamlined fairing optimizes the flow field inside the fan, improves the fan’s operating efficiency and reduces fan noise. - Impeller

The wing-shaped blades and hub are made of aluminum alloy die-casting. The blade installation angle can be adjusted by stopping the machine (must be carried out under the guidance of the manufacturer), which is convenient for users to adjust the performance of the fan according to the actual situation of the tunnel. - Casing Segment

The casing is made of high-quality steel plate rolled round structure, and the flanges at both ends are made of the overall flanging of the casing, which ensures that the casing has a high degree of roundness and rigidity. The motor support is welded to the inner wall of the casing and then sprayed as a whole. - Motor

The special motor can ensure that the fan can run reliably for more than one hour in the high temperature environment of 250°C. The rated voltage is 380V, frequency is 50HZ, and the protection level is 50HZ. The rated voltage of the motor is 380V, the frequency is 50HZ, the protection grade is IP54 (IP55), and the insulation grade is F (H).

Classic Projects

High-speed rail tunnel projects

•Hanxiao Intercity Railway

•Menghua Railway

•Beijing-Shenyang Railway Passenger Dedicated Line

•Jing Zhang Intercity Railway

•Changgan Railway Passenger Dedicated Line

•Hanghuang Railway Passenger Dedicated Line

•Zhejiang section of Suining Railway

•Meishan High Speed Rail

Foreign projects

•Ethiopian Commercial Bank Project

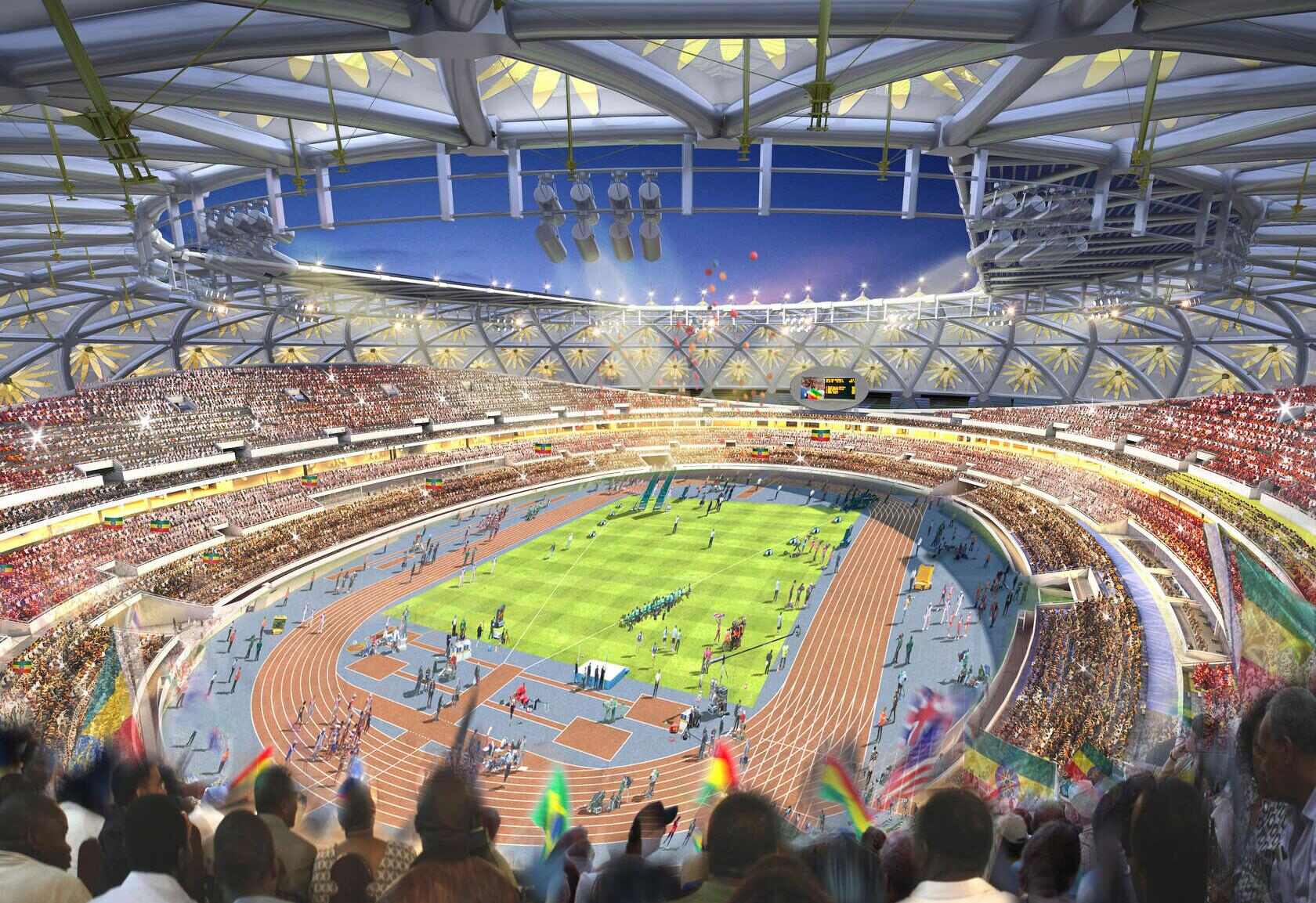

•Ethiopian National Stadium Project

•Ethiopia Bus Station Project

•Equatorial Malabo Airport Project

•Togo Parliament Building Project

Airport high-end projects

•Beijing Daxing New Airport

•Wuhan Tianhe International Airport

•Tianjin Binhai International Airport

•Haikou Meilan Airport

•Changchun Longjia Airport

•Chongqing Jiangbei International Airport

•Equatorial Malabo International Airport